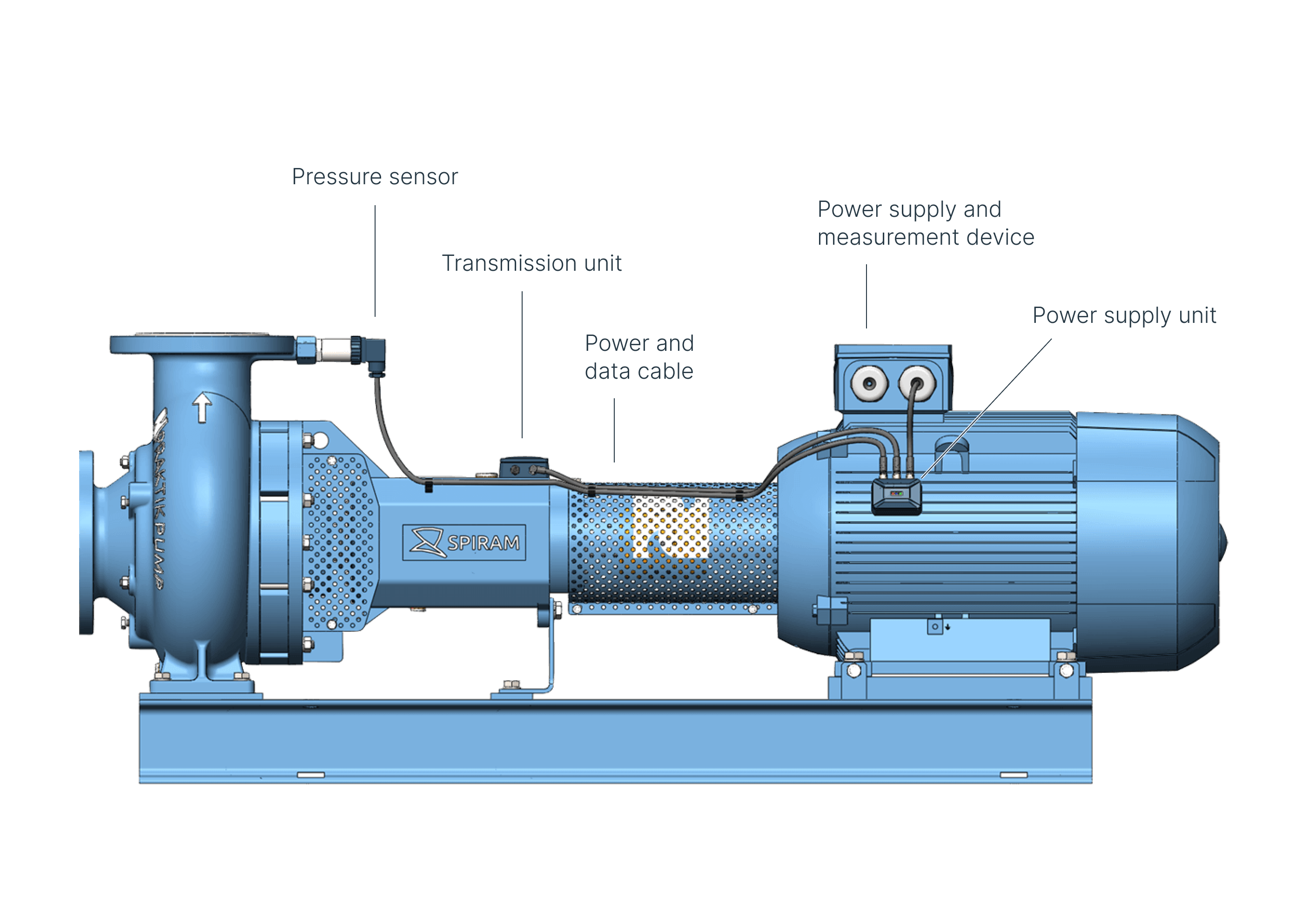

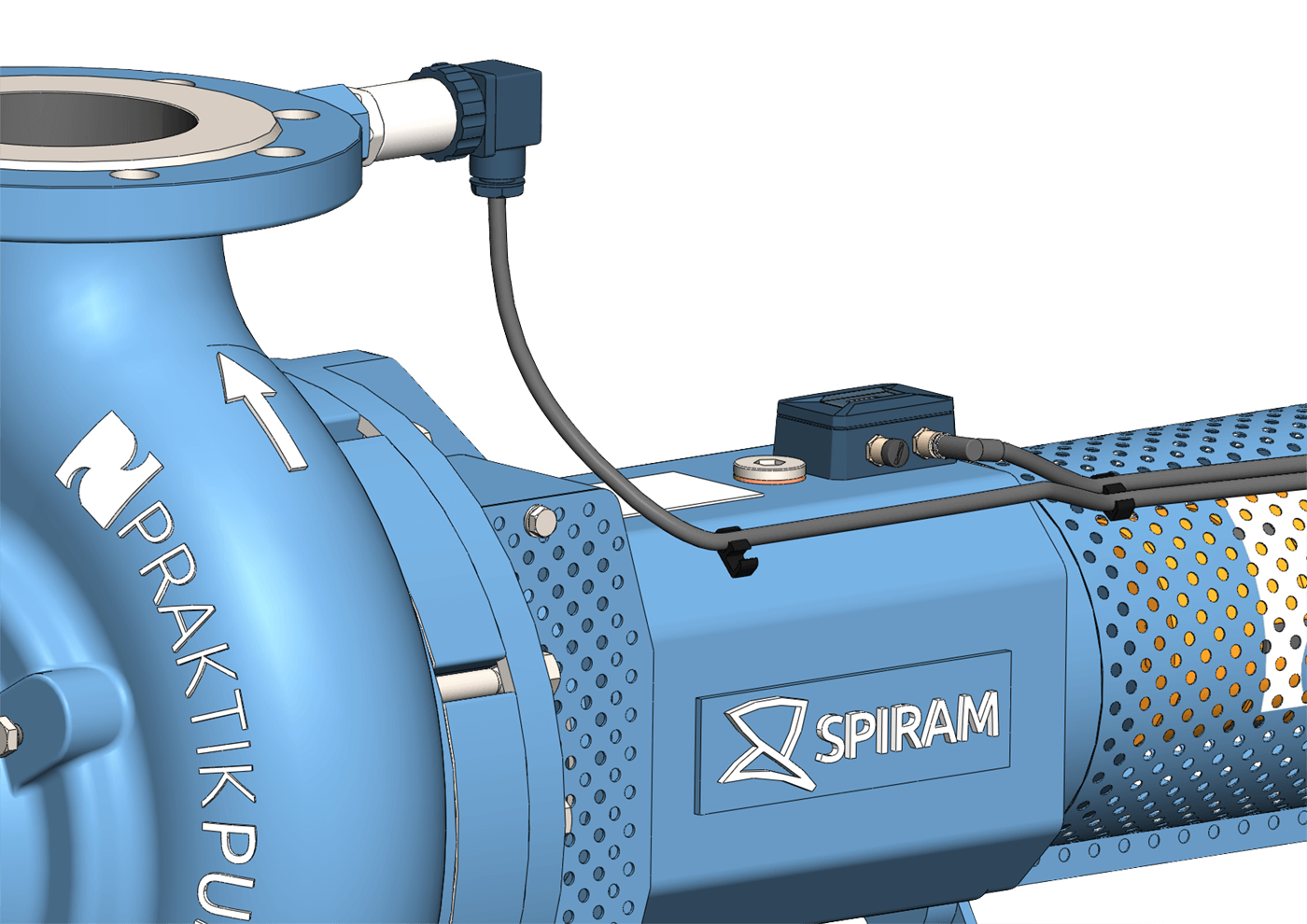

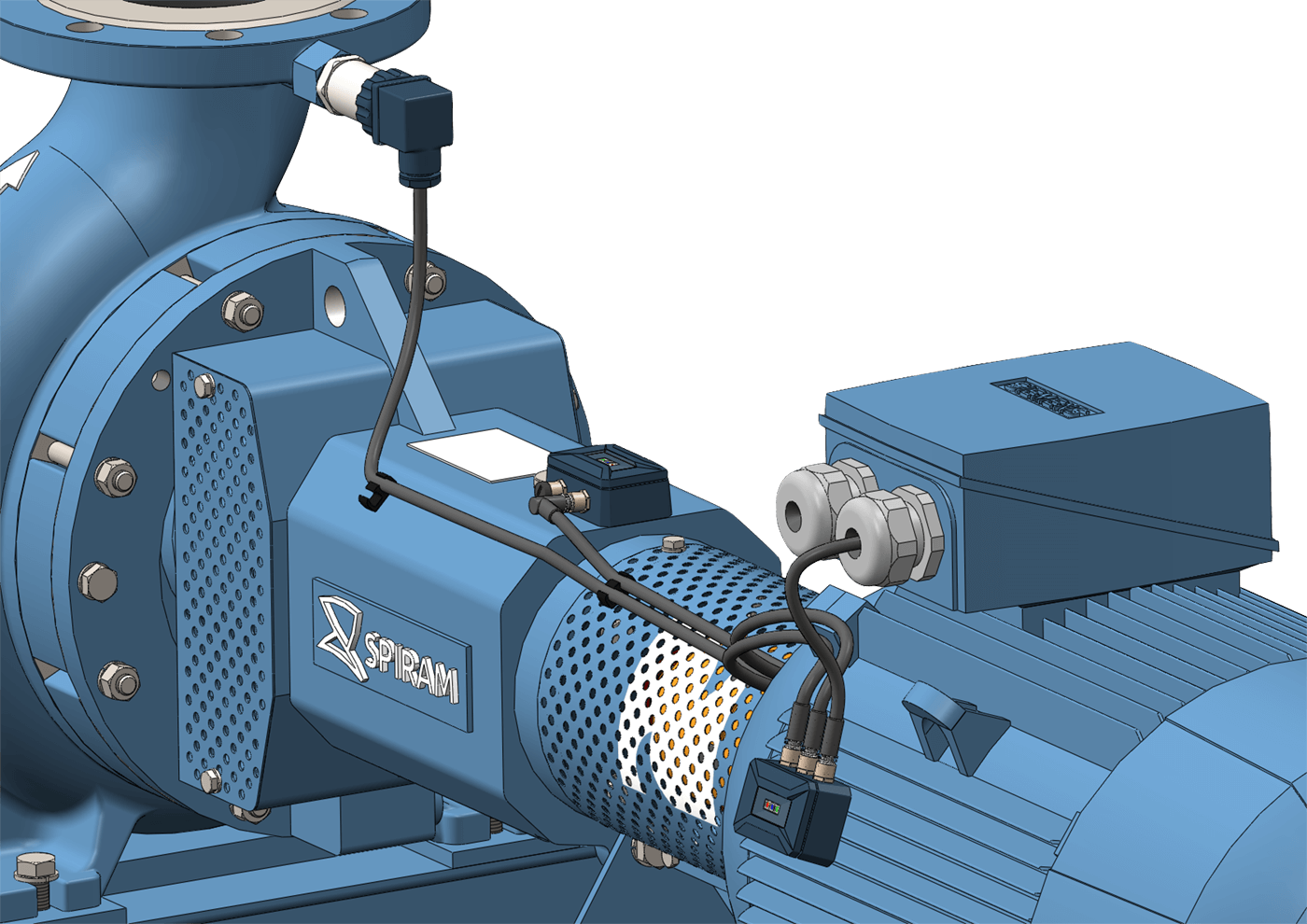

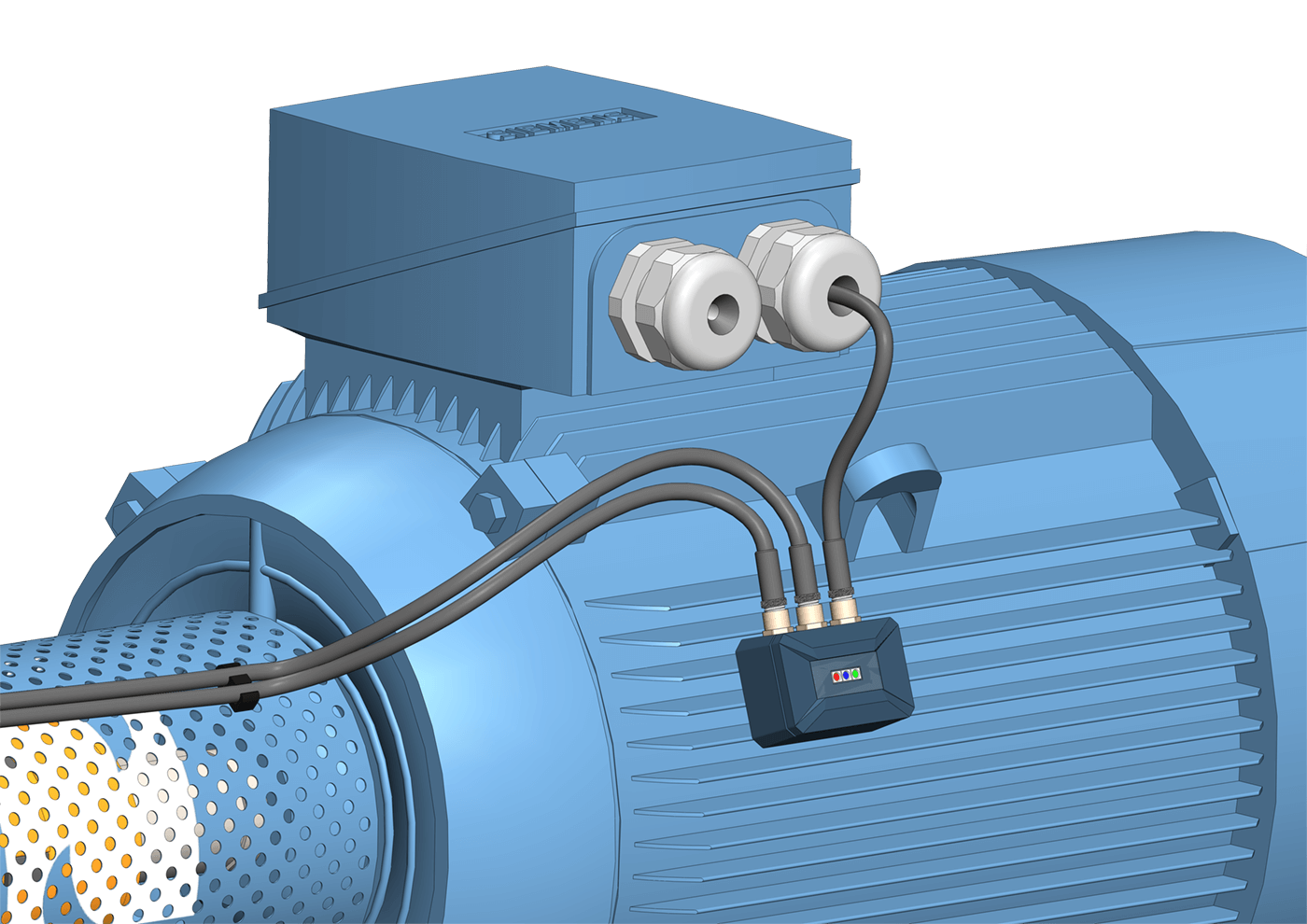

primarily used to provide power required for operation of the entire sensor system and sensing electrical quantities (current and frequency measurement). Also this unit also has a basic module enabling to measure vibrations and temperature. The power supply and measurement device is non-invasively placed in the terminal block of the electric motor and the cable is routed through a grommet, thus keeping the IP protection rating of the machine unaffected. Such a sensing therefore does not interfere with the electric motor, so it does not affect its operation or, for example, its warranty conditions. Moreover, this module provides options for installation of any sensor with outputs (0-5V analog, 4-20mA analog, I2C, SPI/SSI, UART).